-40%

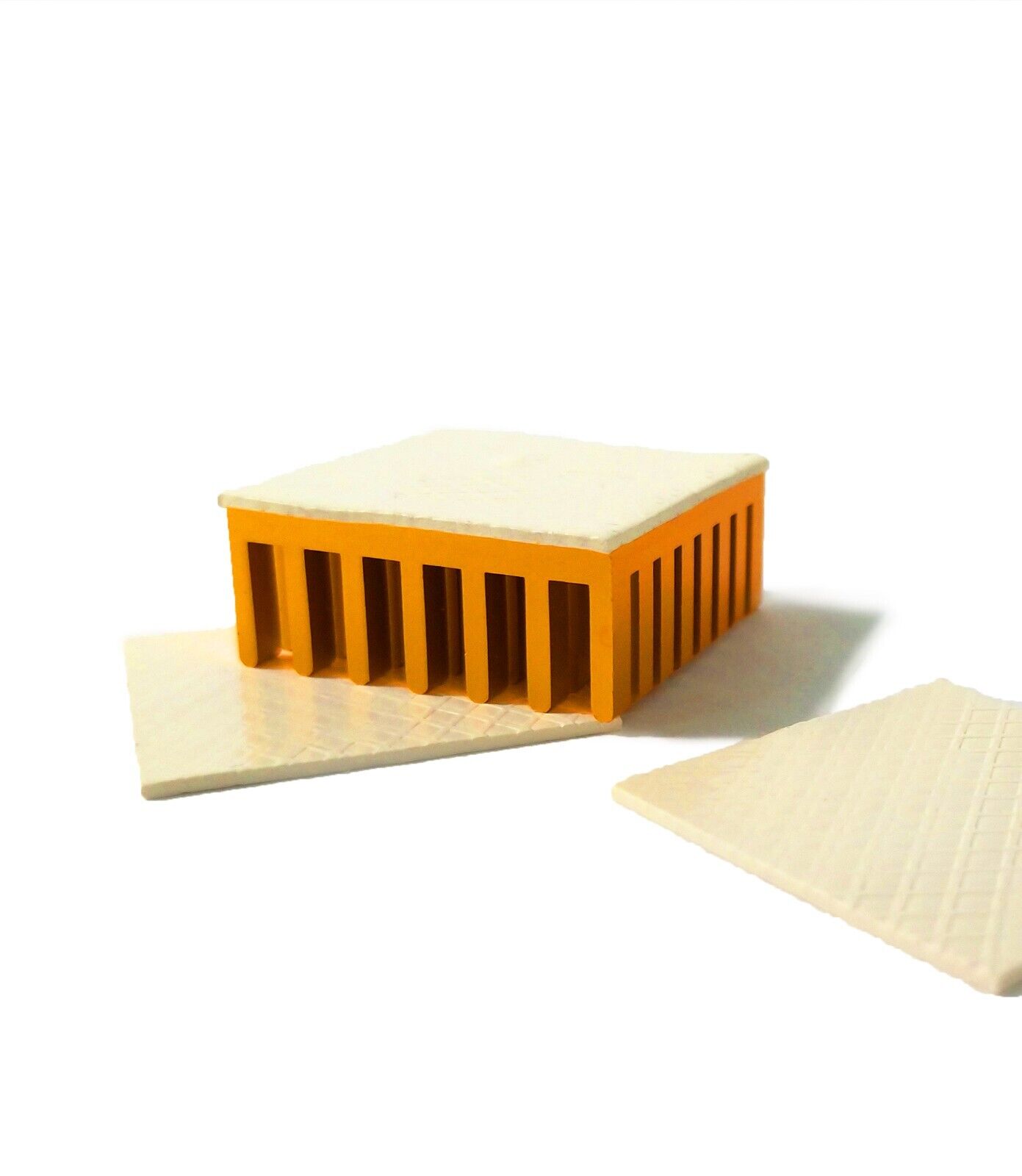

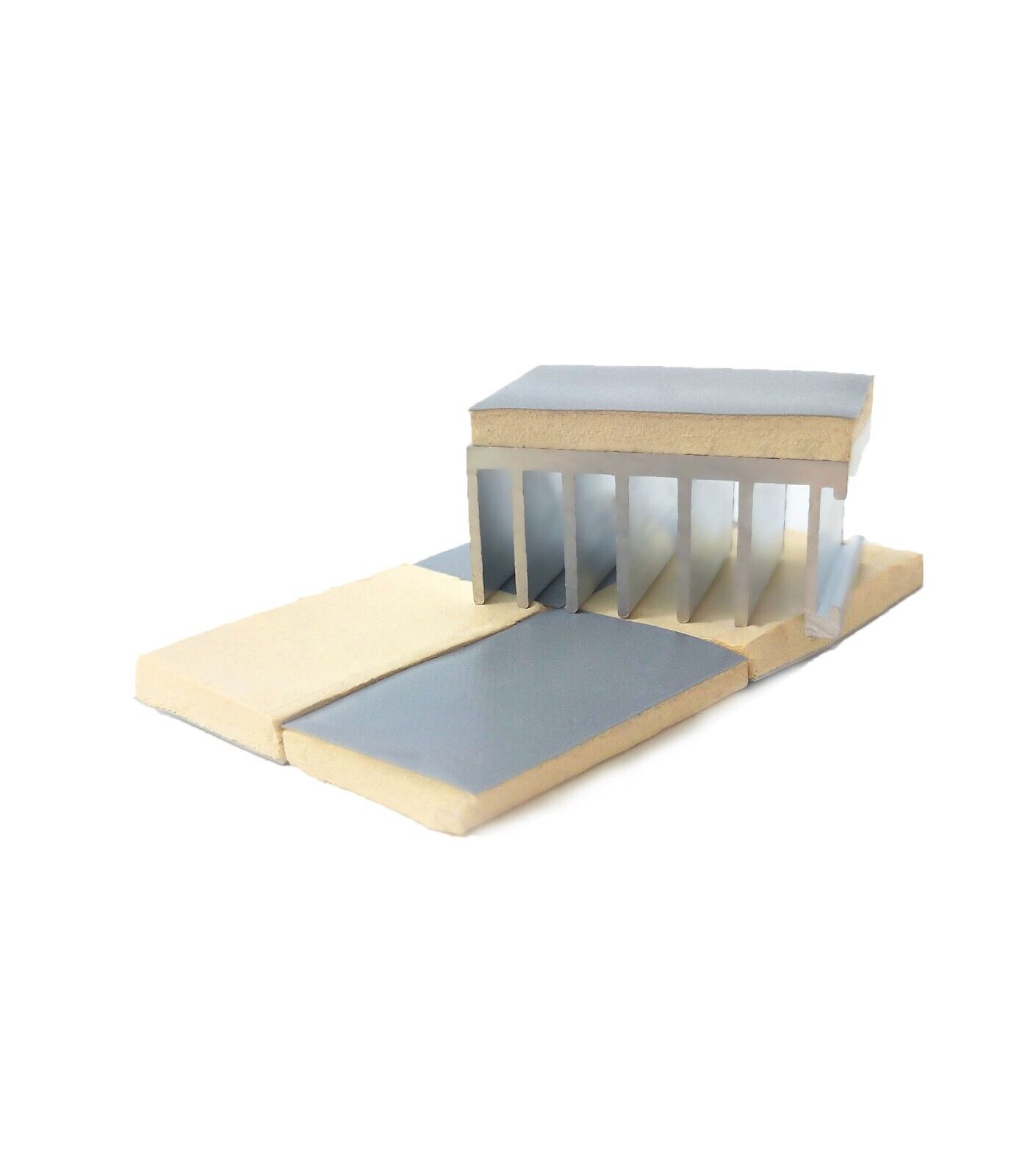

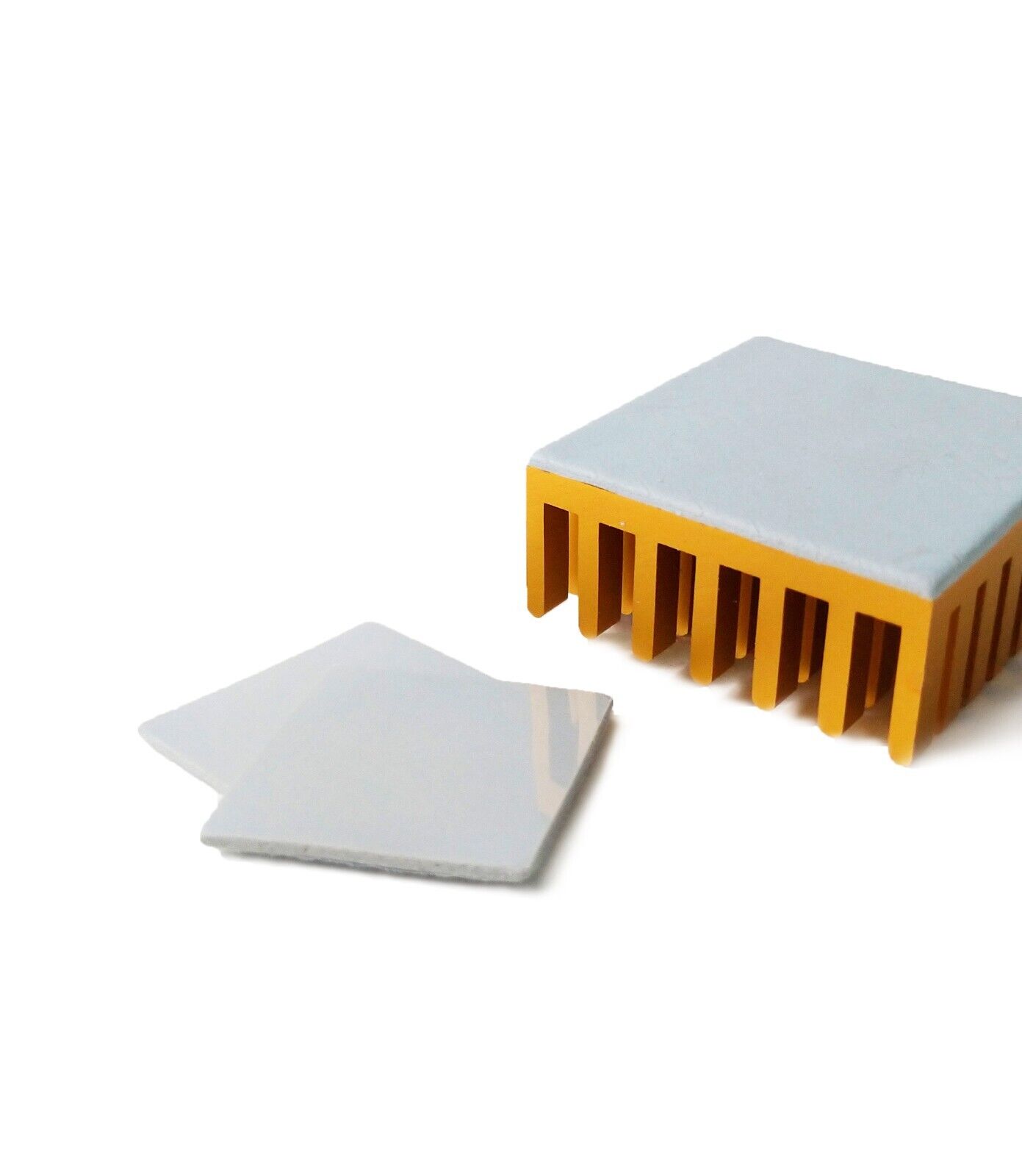

Thermal Pad 12.5 W/mK, 100x100mm, TG-A1250 High Thermal Conductivity

$ 15.3

- Description

- Size Guide

Description

Specification:Thermal Conductivity: 12.5 W/mK

Thickness: 0.5-8.0 mm

Color: Green

Dielectric Breakdown Voltage:

≥

10

KV/mm

Hardness: Shore

OO

55±10

Operating

Temperature: -50~180°C

Density: 3.3 g/cm³

Volume

Resistivity

: 1x10^13 Ohm-m

*The thickness is less than 1.0mm, considering that it's too soft to pick up from the bottom paper, therefore, adjusting the hardness to 50~75 for production line.

Application:

5G, Aerospace, AI, AIoT, AR/MR/SR/VR, Automotive, Consumer Devices, Datacom, Electric Vehicle, Electronic products, Energy Storage, Industrial, Lighting equipment, Medical, Military, Netcom, Panel, Power electronics, Robot, Servers, Smart Home, Telecom

Features:

Good Thermal Conductivity Ability - Using the silicone as the base material, adding thermal conductive powder and flame retardant together to make the mixture to become thermal interface material. Outstanding performance - Low thermal resistance & Electrical insulation Safe and easy to use - You can choose a suitable thickness of thermal pad according to the gap between the heating source and the heat sink. It can be cut to size and easy to install, replacing the traditional thermal paste. Application - Best for high power applications, high-wattage electronics such as electric vehicles, automation, 5G applications, servers, etc.

Operating Manual:

1. When using thermal interface material, keep the product surface clean and dry.

2. A part is covered by a protective film (above) and a release paper (underneath).

3. After tearing off the release paper, gently attach the thermally conductive silicon pad to the heat source.

4. Remove the protective film.

5. Apply components onto the exposed part and apply pressure at fixture. Storage: Store in a cool, dry place away from direct sunlight.